Pipeline Intelligence: Next-Gen Rupture Prediction

Leverage advanced Machine Learning on PIG data to proactively manage pipeline integrity, reduce risks, and cut operational costs for the Oil & Gas Industry.

Stop reacting. Start predicting. Enhance safety and efficiency with Pignostics.

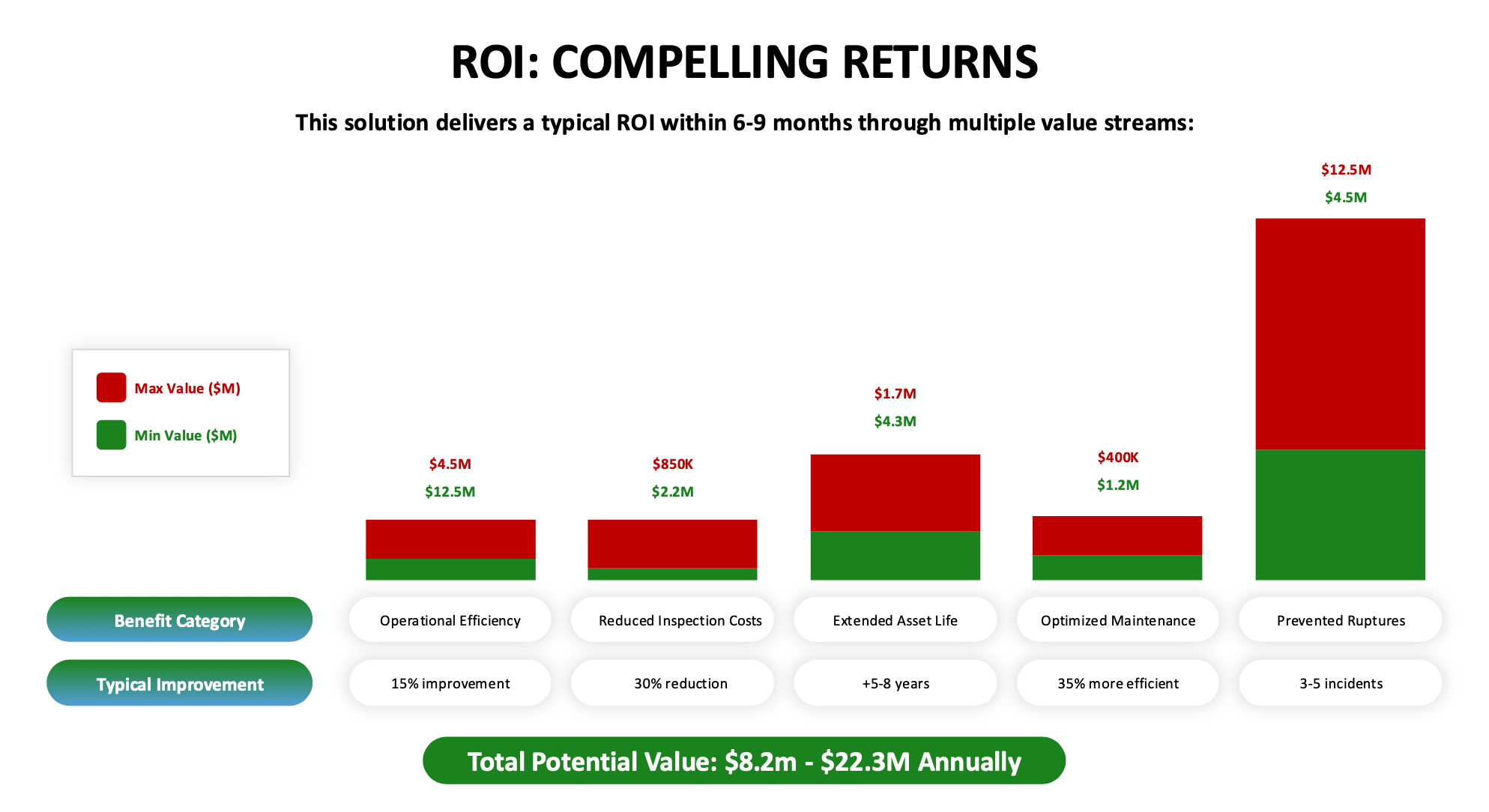

Unlock Compelling Returns & Enhance Operations

Pipeline Intelligence delivers quantifiable results, translating predictive power into tangible business value. Clients typically achieve a full Return on Investment within 6-9 months, driven by multiple value streams.

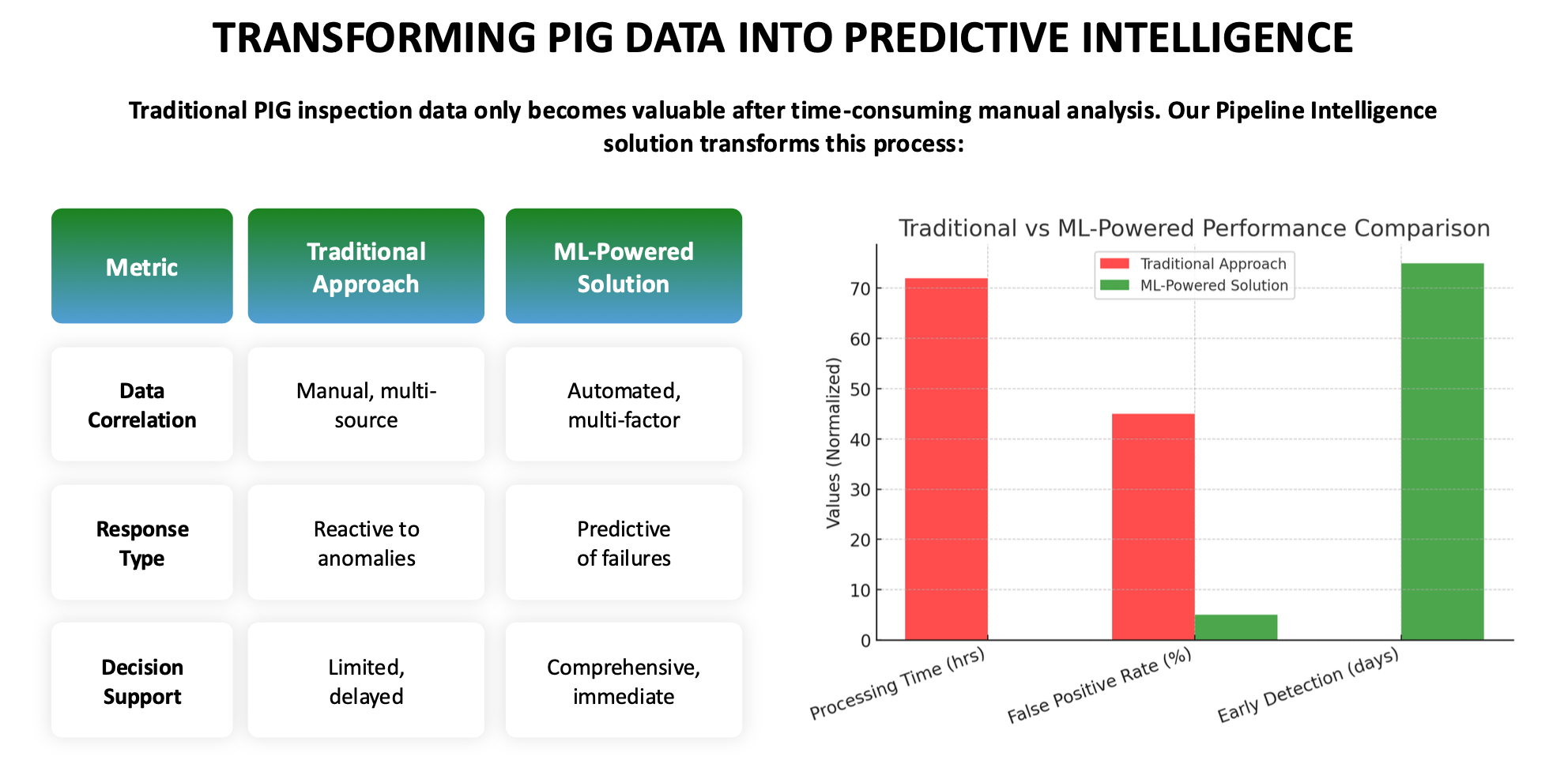

Traditional vs. ML-Powered Performance

Traditional Approach

- • Processing Time: 72+ hours

- • False Positive Rate: 45%

- • Detection Lead Time: 0-7 days

Pignosis ML-Powered

- • Processing Time: 25 seconds

- • False Positive Rate: 8%

- • Detection Lead Time: 60-90 days

Proven Success with Industry Leaders

Pipeline operators across North America are already realizing significant benefits from implementing Pipeline Intelligence (Pignosis).

Major North American Pipeline Operator

- 94% Prediction Accuracy Achieved (New Capability)

- 4 Potential Ruptures Prevented

- $8.7M in Estimated Savings

- 76% Reduction in Emergency Repair Costs (from $3.2M to $768k annually)

- Inspection Intervals Extended by 40% (60 to 84 days)

- Detection Lead Time Increased 9-12x (from 0-7 days to 65-90 days)

Canadian Energy Infrastructure Company

- Analysis Processing Time Reduced by 99.99% (72 hours to 25 seconds)

- Shifted Decision Support from Post-Event to Predictive

- Gained End-to-End Visibility with Integrated Health Monitoring

- Achieved Full ROI within 7 Months (Rapid Payback)

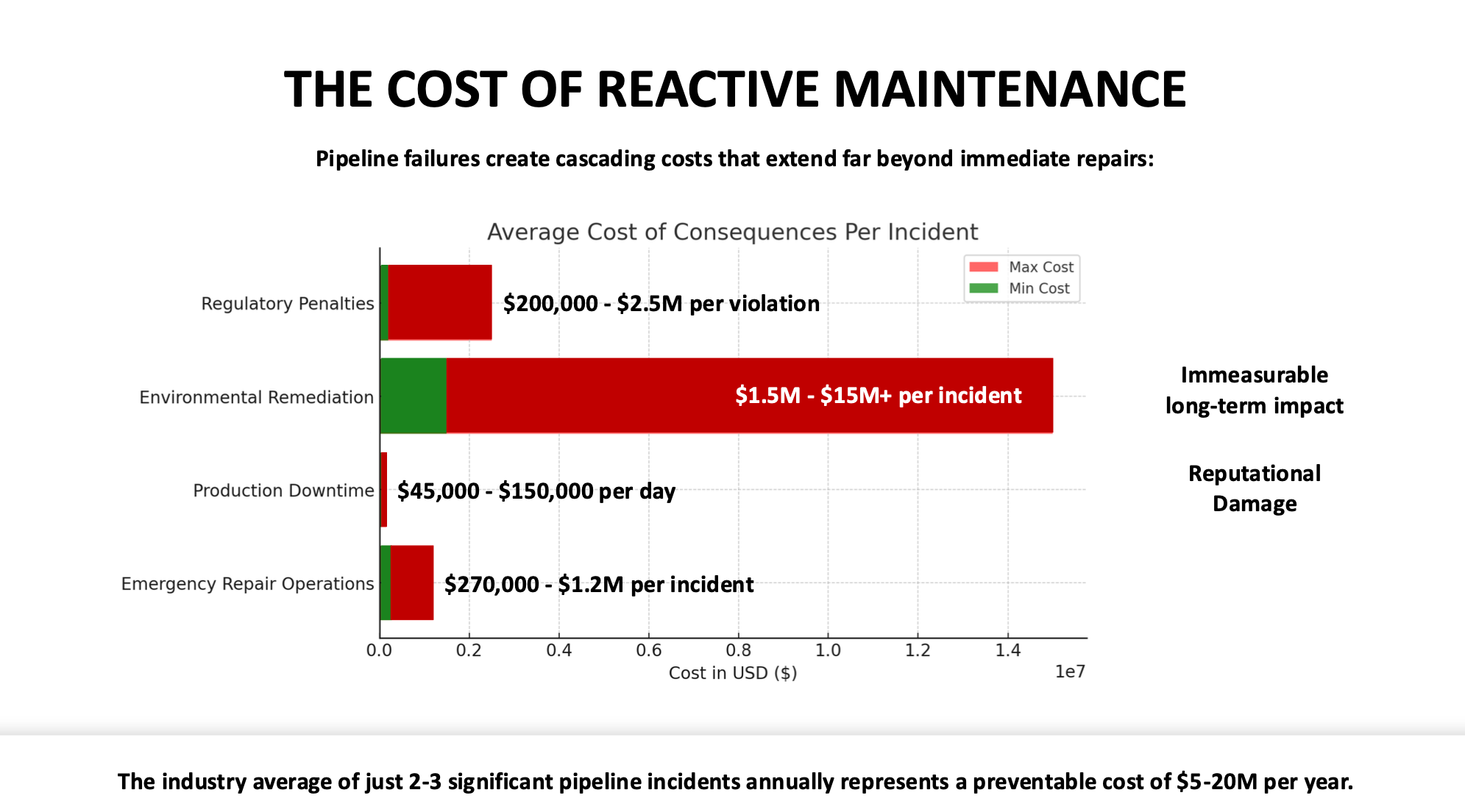

The High Cost of Reactive Pipeline Maintenance

Traditional pipeline inspection methods offer only a backward look, leaving Midstream operators exposed to unforeseen failures. These incidents trigger a cascade of costs far exceeding immediate repairs, impacting safety, the environment, and your bottom line. The industry average of just 2-3 significant incidents annually represents a preventable cost of $5-20M per year.

Traditional inspection methods can miss critical pipeline issues.

Emergency Repairs

$270k - $1.2M+ per incident

Environmental Remediation

$1.5M - $15M+ per incident

Regulatory Penalties

$200k - $2.5M per violation

Production Downtime

$45k - $150k per day

Reputational Damage

Immeasurable long-term impact

Retrospective Insights Only

Traditional methods react, not predict

The Technical Advantage: How Pignosis Works

Our solution utilizes cutting-edge technology, specifically optimized for pipeline operations, running on a robust and secure Microsoft Azure infrastructure. We turn complex data into actionable intelligence.

Advanced Machine Learning Pipeline

Feature Engineering

Extracts 137+ critical indicators from standard PIG data, revealing hidden patterns undetectable by human analysis.

Ensemble Models

Combines gradient boosting with deep neural networks to maximize prediction accuracy across diverse failure modes.

Progressive Learning

Continuously improves prediction capability with each new inspection cycle, enhancing accuracy over time.

Early Anomaly Detection

Identifies subtle precursors to failure 60-90 days before conventional methods, enabling timely intervention.

Secure Microsoft Azure Infrastructure

Azure Machine Learning

Powers enterprise-grade AI model training and deployment without requiring specialized internal staff.

Azure DataBricks

Transforms complex PIG data into actionable intelligence through efficient processing and visualization.

Security & Compliance

Provides industry-standard protection, meeting rigorous Oil & Gas security requirements.

System Integration

Connects seamlessly with existing SCADA and ERP systems, preserving investments in current infrastructure.

Safety First: Field-Proven Solutions

Our solutions prioritize safety and operational excellence in the field.

Secure Your Pipeline's Future Today

Stop reacting to failures and start proactively managing your pipeline integrity. Discover how Pipeline Intelligence (Pignosis) can deliver predictive insights, reduce operational risks, enhance safety, and generate significant cost savings for your Midstream operations.